Since Pickware ERP 4.0, we support chaotic warehousing. This means that several items can be assigned to one bin location and that one item can be stored in several bin locations. The assignment of an item to bin locations can be done either in the backend in the item details or within the WMS Inventory App.

Assign bin locations with Pickware ERP

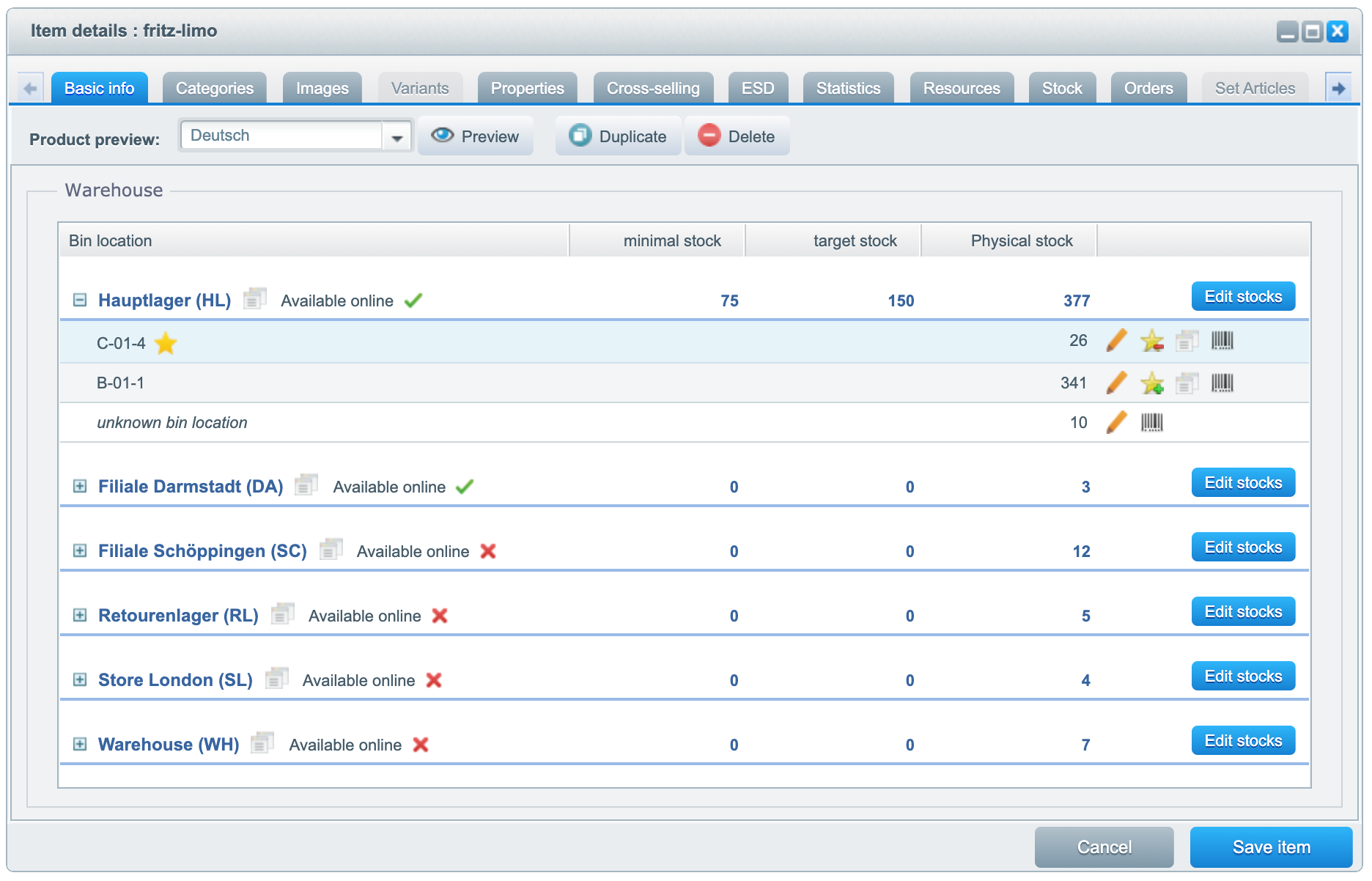

Open any item and scroll down the Basic info tab until you see the Warehouse section. Here you can edit both the stock and the bin location.

Each warehouse maintained in the shop is listed here with the associated physical stocks of the item.Click on the plus symbol to view the stocks for each bin location within a warehouse. On the right-hand side of the line of each bin location, the following options are available for editing:

- Pencil icon: Make stock adjustments.

- Star icon: Specify whether the bin location is the item's default bin location. A limit of one default bin per item and per warehouse is allowed.

- Box icon: Open the bin location details to see the other items in this bin location.

- Barcode icon: Mark the bin location for label printing. This option is only available when using Pickware WMS or POS.

The standard storage bin is important when you set the status of customer orders to Completely delivered. In this case, stock is primarily taken out of the standard storage bin.

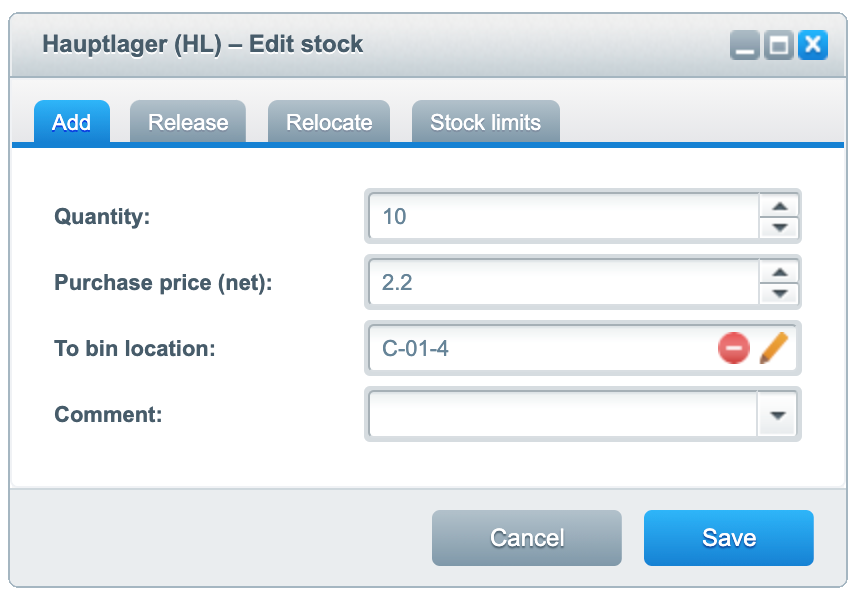

If you want to transfer an item in, out or to another location via the backend, click on Edit stocks for the corresponding warehouse or click on the pencil icon for the corresponding bin location. The following window opens:

Click on the appropriate tab depending on whether you want to add, release or relocate the item. If you click on the pencil symbol when editing the target bin location, you can either choose from all the bins already assigned to the item or from every bin location created in the warehouse. Alternatively, it is also possible not to define a bin location for a stock entry. In this case, simply click on the delete symbol and a stock entry will be made for a unknown bin location.

You can also easily make stock changes via CSV-Import.

The tab Stock limits allows you to set a minimum stock and a target stock. The minimum stock determines which items are proposed to you for reordering when creating a new supplier order. The target stock specifies the quantity to which the warehouse is to be restocked in the event of a re-order. Therefore, the target stock must be at least as large as the minimum stock.

Assign bin locations with Pickware WMS

To store, release or relocate items, navigate to the Item tab in the app, make sure the correct warehouse is selected at the top of the screen and then select an item via search or scan. You can now choose between three modes: Store, Release or Relocate.

- Store items: Enter the quantity to be stored and select the bin location. The last purchase price is already entered, but you can also adjust it. If you want to store items from a supplier order that you created with Pickware ERP, there is a separate process for this: Store supplier orders.

- Release items: Enter the quantity and the bin location from which you want to release the goods.

- Relocate items: Here you can select from which to which bin location you want to relocate. If you click on To bin location, you can create a new bin location using the plus icon in the upper right corner. To move an item to another warehouse, use the To warehouse field. Please note that you need the appropriate user authorisation to change bin locations in the app.

For all processes, you can always scan the bin location in order to select it, if you use bin location labels. You can also enter comments. The standard comments can be customised in the Pickware ERP plugin configuration. If you select Free text, you can enter an individual comment.

You can find more about warehouse management in the backend here. This article describes how you can (automatically) generate bin locations in the backend. You can also manage your stocks via CSV import. You can find out more about this here.